How to Choose the Best Sheet Cutter for ACP Materials

By:Admin

The construction industry has seen significant advancements in technology and materials throughout the years. Among these advancements is the Acp Sheet Cutter, a revolutionary tool that has been changing the way construction professionals work with aluminum composite panels (ACP). This innovative cutting tool has been developed and manufactured by a leading company in the construction industry, known for its commitment to providing high-quality and reliable products for construction professionals.

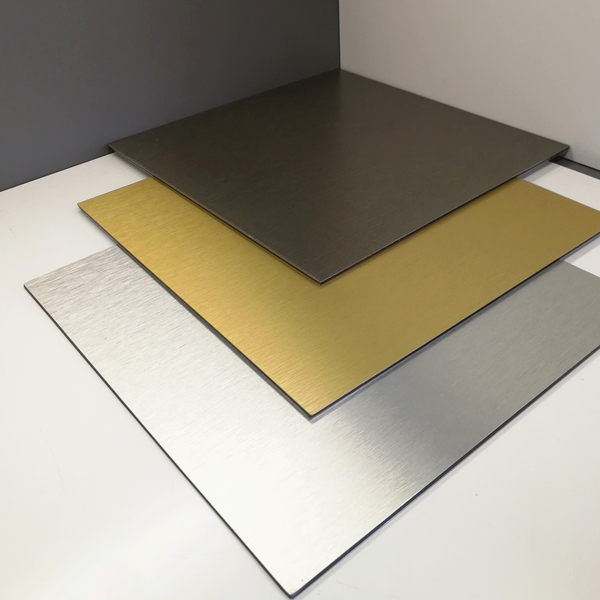

The Acp Sheet Cutter is designed to meet the specific needs of contractors, architects, and designers who work with ACP. These panels are widely used in the construction industry due to their durability, lightweight nature, and aesthetic appeal. However, working with ACP can be challenging, especially when it comes to cutting and shaping the panels to fit specific design requirements. This is where the Acp Sheet Cutter comes into play, offering a precise and efficient solution for cutting ACP with ease and accuracy.

The company behind the Acp Sheet Cutter has a strong track record of delivering innovative and effective solutions for the construction industry. With a focus on research and development, the company has been at the forefront of introducing new technologies and tools that enhance the efficiency and quality of construction projects. The Acp Sheet Cutter is just one example of the company's commitment to providing innovative solutions that address the evolving needs of construction professionals.

The Acp Sheet Cutter is equipped with advanced cutting technology that allows for precise and clean cuts on ACP. Its ergonomic design and user-friendly interface make it easy for construction professionals to operate, saving time and effort in the cutting process. Whether it's for simple straight cuts or complex shapes and angles, the Acp Sheet Cutter delivers consistent and reliable results, making it an essential tool for anyone working with ACP.

One of the key benefits of the Acp Sheet Cutter is its ability to enhance productivity on construction sites. With its fast and accurate cutting capabilities, the Acp Sheet Cutter helps reduce manual labor and minimize waste, ultimately leading to cost savings for construction projects. Its portability and versatility also make it a valuable asset for contractors and builders working on various job sites and projects.

In addition to its practical benefits, the Acp Sheet Cutter also contributes to the safety of construction professionals. By minimizing the use of traditional cutting tools such as saws and blades, the Acp Sheet Cutter reduces the risk of accidents and injuries on job sites. This not only promotes a safer work environment but also helps construction companies adhere to safety regulations and standards.

The company's commitment to quality and customer satisfaction is evident in the design and performance of the Acp Sheet Cutter. The tool is built to withstand the rigors of construction work and is backed by comprehensive support and service from the company. With a strong focus on reliability and durability, the Acp Sheet Cutter has garnered praise from construction professionals for its performance and longevity.

As the construction industry continues to evolve, tools and technologies like the Acp Sheet Cutter play a crucial role in driving efficiency and innovation. The company behind this groundbreaking tool remains dedicated to pushing the boundaries of what's possible in construction, providing the industry with cutting-edge solutions that meet the evolving needs of construction professionals.

In conclusion, the Acp Sheet Cutter stands as a testament to the company's commitment to excellence and innovation in the construction industry. Its impact on the efficiency, productivity, and safety of construction projects has been widely recognized, establishing it as a valuable asset for construction professionals. With its advanced cutting capabilities and user-friendly design, the Acp Sheet Cutter is poised to continue revolutionizing the way ACP is handled in construction, setting a new standard for precision and performance in the industry.

Company News & Blog

The Versatility and Benefits of Aluminum Honeycomb Structure

Aluminum Honeycomb: Revolutionary Lightweight Material Offers Endless Possibilities(Company Introduction)In today's demanding industrial landscape, finding innovative solutions that address the need for lightweight yet sturdy materials has become more crucial than ever. This is where Aluminum Honeycomb, developed by leading materials manufacturer (company name omitted), comes into play. With its unparalleled strength-to-weight ratio, versatility, and eco-friendly properties, Aluminum Honeycomb has quickly become a game-changer in numerous industries.(Opening Paragraph)(Company name omitted), a pioneer in advanced materials, is proud to present Aluminum Honeycomb, the latest addition to their repertoire of cutting-edge materials. This innovative lightweight material has garnered attention across various sectors, from aerospace and construction to automotive and marine industries. With its unique cellular structure and exceptional performance characteristics, Aluminum Honeycomb is the answer to the increasing demand for robust, yet low weight, materials.(Aluminum Honeycomb: Strength, Versatility, and Lightweight Properties)At the heart of this revolutionary material lies a remarkable cellular structure, comprised of hexagonal shapes known as honeycombs. Aluminum Honeycomb is engineered by bonding two aluminum sheets to a honeycomb core, resulting in an extremely strong and rigid panel. This structure allows the material to provide outstanding strength while maintaining an incredibly low weight.The application possibilities of Aluminum Honeycomb in the aerospace industry are vast. By replacing traditional heavy materials with Aluminum Honeycomb panels, aircraft weight can be significantly reduced, leading to improved fuel efficiency. Moreover, the panels' exceptional shear strength and vibration-dampening properties make them ideal for aircraft flooring, interior panels, and even engine nacelles. In the construction sector, Aluminum Honeycomb finds extensive usage in architecture and interior design. Its lightweight nature facilitates easy installation while maintaining a high level of strength. This makes it an excellent choice for cladding, curtain walls, partitions, flooring, ceilings, and other architectural elements. The material's fire-resistant properties further enhance its suitability for building exteriors, ensuring both safety and durability.The automotive industry, constantly seeking ways to enhance fuel efficiency without compromising safety, has also embraced Aluminum Honeycomb. Lightweight structures produced with Aluminum Honeycomb help to reduce vehicle weight, resulting in improved fuel economy, reduced emissions, and enhanced performance. Moreover, the material's energy-absorbing characteristics make it a perfect fit for safety features such as impact panels, bumpers, and crash boxes, offering increased protection to the vehicle and its occupants.Similarly, the marine industry has recognized the advantages of Aluminum Honeycomb panels. Lighter boats experience less drag, leading to higher speeds and fuel efficiency. Additionally, the material's resistance to moisture, corrosion, and impact makes it suitable for various marine applications, including hulls, decks, bulkheads, and interiors.(Eco-Friendly Material with a Sustainable Future)In addition to its exceptional properties, Aluminum Honeycomb is also an eco-friendly alternative. With an increasing focus on sustainability, the material stands out due to its recyclability. Aluminum is one of the most sustainable materials available, as it can be recycled indefinitely without losing its inherent qualities. By adopting Aluminum Honeycomb, industries can significantly reduce their carbon footprint while designing and manufacturing sustainable products.(Conclusion)In conclusion, Aluminum Honeycomb, offered by (company name omitted), has revolutionized numerous industries with its exceptional strength-to-weight ratio, versatility, and eco-friendly properties. From aerospace to automotive, construction to marine sectors, this lightweight material provides endless possibilities for creating safer, more efficient, and sustainable products. As industries continue to evolve and seek advanced solutions, Aluminum Honeycomb will undoubtedly maintain its position as a game-changing material, paving the way for a brighter future.

How Copper Nickel Sheets are Beneficial for Industrial Applications

Copper Nickel Sheets: A Durable and Versatile Solution for Industrial ApplicationsCopper Nickel Sheets, also known as Cupronickel Sheets, are a popular material used in a wide range of industrial applications. The alloy is a combination of copper, nickel, and other trace elements, which gives it excellent corrosion resistance, high strength, good ductility, and thermal conductivity. These properties make Copper Nickel Sheets an ideal choice for a variety of applications that require durability, reliability, and resistance to harsh environments.One of the main benefits of Copper Nickel Sheets is their resistance to corrosion and erosion. The alloy is particularly resistant to seawater corrosion, making it an excellent material for marine and offshore industries. It is also resistant to biofouling, meaning that it resists the growth of marine organisms that can cause damage to structures and equipment. This durability makes it a popular choice for use in heat exchangers, condensers, and piping systems.Another advantage of Copper Nickel Sheets is their high strength and ductility. They can be easily formed, welded, and fabricated to meet specific design requirements. This flexibility makes them suitable for a range of applications, including electrical components, shipbuilding, and automotive parts. The alloy is also highly resistant to fatigue and stress-corrosion cracking, making it an ideal choice for critical applications that require a high level of reliability.Copper Nickel Sheets also have good thermal conductivity, which makes them suitable for heat exchange applications. They are commonly used in heat exchangers, condensers, and evaporators in power generation plants, chemical plants, and oil and gas refineries. Their high thermal conductivity means that they can transfer heat efficiently, which reduces energy costs and improves system performance.One company that specializes in the manufacturing and supply of Copper Nickel Sheets is [company name removed]. The company has been providing high-quality Copper Nickel Sheets to clients in various industries for more than a decade. They have a range of Copper Nickel Sheets available in different grades, sizes, and thicknesses, and can also provide custom fabrication services to meet specific requirements.[Company name removed] prides itself on the quality of its products, and their Copper Nickel Sheets are tested and certified to meet industry standards. Their products are also environmentally friendly, as they are made from 100% recyclable materials. The company is committed to providing sustainable solutions to its clients, and their Copper Nickel Sheets are an excellent choice for industries looking to reduce their carbon footprint.In addition to their high-quality products, [Company name removed] also offers excellent customer service and technical support. Their team of experts can provide advice on material selection, design, and fabrication, and can work closely with clients to ensure that their specific requirements are met.Overall, Copper Nickel Sheets are a durable and versatile material that is widely used in various industries. Their excellent resistance to corrosion, high strength, and good thermal conductivity make them ideal for a range of applications, from marine and offshore industries to power generation plants and chemical refineries. With their commitment to quality and sustainability, [company name removed] is a leading supplier of Copper Nickel Sheets, and a trusted partner for clients looking for reliable and cost-effective solutions.

Aluminum Composite Panel Specifications: A Comprehensive Overview of Technical Details

[Company Introduction][Company Name], a leading manufacturer and supplier of Aluminum Composite Panels (ACPs), is proud to announce the release of their latest product line, set to revolutionize the construction and design industry. With a strong commitment to quality and innovation, [Company Name] has been providing exceptional ACP solutions to architects, builders, and contractors globally.[Aluminum Composite Panel Specifications][Company Name] is pleased to present their new range of Aluminum Composite Panels (ACPs), which boast an impressive set of specifications:1. Material Composition: The panels are composed of a core material sandwiched between two layers of aluminum sheets. The high-density polyethylene (HDPE) core provides excellent rigidity and strength whilst remaining lightweight.2. Thickness Options: [Company Name] offers a wide range of panel thicknesses to cater to various applications. The options include 3mm, 4mm, and 6mm, allowing clients to choose the most suitable thickness for their specific project requirements.3. Surface Coating: The aluminum sheets are coated with a high-quality paint finish, providing superior resistance to weather conditions, UV radiation, and pollution. This ensures the durability and longevity of the ACPs, even in harsh environments.4. Fire Resistance: [Company Name] ACPs are manufactured to adhere to stringent fire safety standards. The panels are treated with fire-resistant additives during production, resulting in a fire rating of Class A2, according to relevant international standards.5. Wide Color Selection: The ACPs are available in a broad spectrum of colors, offering designers and architects unlimited creative possibilities. From vibrant shades to subtle hues, [Company Name] aims to provide aesthetically pleasing options to suit every design concept.6. Easy Fabrication: The lightweight nature of the panels makes them effortless to cut, bend, and shape. This ensures streamlined installation, reduced labor costs, and greater design flexibility.7. Environmental Responsibility: [Company Name] is committed to sustainable practices and environmentally friendly manufacturing. The ACPs are recyclable, and the production process incorporates energy-saving and waste reduction measures.With these advanced specifications, [Company Name] aims to provide architects, builders, and contractors with a superior solution for their construction and design projects. The versatility, durability, and aesthetic appeal of the ACPs make them an ideal choice for both interior and exterior applications.[Company Name] understands the importance of efficient project timelines and cost-effectiveness. Therefore, the company offers competitive pricing without compromising on quality. Additionally, their ACPs come with comprehensive technical support and excellent customer service, ensuring a seamless experience from start to finish.The release of [Company Name]'s new range of Aluminum Composite Panels is set to further solidify their position as a leader in the industry. With a commitment to innovation, quality, and customer satisfaction, [Company Name] is poised to make a significant impact on the construction and design landscape.[Conclusion][Company Name] encourages industry professionals to explore their new range of Aluminum Composite Panels and discover the endless possibilities they offer. Whether it's for a commercial building, residential project, or retail space, [Company Name] can provide the perfect ACP solution to bring designs to life.

Guide to Understanding Aluminium Composite Panel Specifications

article on the topic.Aluminum Composite Panel Specifications Enhance Building Envelope PerformanceAs the architectural industry continues to evolve, building envelopes are becoming increasingly sophisticated. Engineers, architects, and contractors are investing in advanced technologies and materials to achieve energy-efficient, sustainable, and aesthetically pleasing building structures. Aluminum composite panels are among the top materials that are transforming the building envelope industry. With their unique design and properties, they provide builders with a versatile and reliable solution for constructing walls, ceilings, and facades.Aluminum composite panels are made of two sheets of aluminum that are bonded to a non-aluminum core material. The core material could be made of polyethylene, fire-retardant mineral core, or other types of composite materials. The combination of aluminum and the core material provides the panels with excellent mechanical strength, durability, and resistance to weather and fire. The panels are also lightweight and easy to install, which makes them ideal for cladding, curtain walls, and interior decoration.In recent years, the demand for aluminum composite panels has increased significantly due to their numerous benefits. The panels offer excellent thermal insulation, sound insulation, and moisture resistance, which can help improve energy efficiency and occupant comfort. They also come in various colors, finishes, and textures, making them suitable for various architectural styles and applications. However, with the rise in demand for aluminum composite panels, some manufacturers have been producing substandard panels that pose serious safety risks. The use of combustible core materials, poor quality adhesives, and inadequate testing and certifications have led to several high-profile fires and safety incidents. As a result, many building codes and regulations have been revised, and building owners and contractors are increasingly becoming concerned about the safety and quality of aluminum composite panels.To help address these concerns, reputable manufacturers are providing comprehensive specifications and testing data to ensure that the panels meet the highest standards of performance and safety. One such manufacturer is {}, which offers a range of aluminum composite panels that are rigorously tested and certified to meet international standards.For example, their panels are tested for fire resistance, with the fire-rated panels having a fire rating of up to 2 hours. The panels also undergo rigorous testing for mechanical strength, adhesion, weatherability, sound insulation, and thermal insulation. In addition, the panels are certified by various independent testing agencies, such as ASTM, EN, AS, and PSB, to ensure that they meet the necessary safety and quality standards.Apart from the safety and performance aspects, {} offers a wide range of aluminum composite panel specifications to suit different project requirements. The panels come in various sizes, thicknesses, colors, and finishes, allowing builders to create customized designs that meet their exact needs. For instance, the panels can be coated with different finishes, such as PVDF, polyester, and nano, which provide enhanced weather resistance and color stability.Also, the panels can be fabricated into different shapes, such as curves, angles, and triangles, to achieve unique designs and textures. This flexibility in design and fabrication helps architects and builders to create visually appealing and innovative building envelopes that reflect their creativity and style.With the increasing demand for energy-efficient, sustainable, and aesthetically pleasing buildings, the use of aluminum composite panels is expected to continue growing. However, it is essential that builders use high-quality, certified panels that meet the necessary safety and performance standards. Manufacturers like {} provide comprehensive aluminum composite panel specifications and testing data that can help builders make informed decisions and ensure that their buildings meet the required standards of safety, quality, and sustainability.In conclusion, aluminum composite panels are a reliable and versatile solution for constructing building envelopes that meet the demands of the modern architectural industry. Builders and architects who are looking for an advanced and aesthetic building material should consider the benefits of aluminum composite panels. To ensure that the panels meet the necessary safety and performance standards, one should choose a reputable manufacturer that provides comprehensive specifications and testing data. With the right panels and specifications, builders can create technically advanced, aesthetically pleasing, and safe buildings that meet the needs of the present and future generations.

Aluminium Composite Panels in High Demand for Building Projects

Aluminium composite panels are highly popular in the construction industry due to their durability, versatility, and low maintenance costs. Stacbond, a leading manufacturer of the aluminium composite panel, has grown to become one of the most well-known brands in the industry. However, recent events have led to the removal of the brand name from the market.Stacbond Aluminium Composite Panel Company is a division of Grupo Ténica S.L., a leading manufacturer of architectural and industrial building materials. The company has been operating for over 40 years and has been providing high-quality aluminium composite panels to its customers during this time.The company prides itself on its ability to provide customers with a complete range of services, from design to logistics. With a strong focus on research and development, the company has been able to manufacture products that meet the needs of the industry. Stacbond has consistently invested in the latest equipment and technology to improve the quality of its products. The company’s innovative use of aluminium, in combination with other materials like ceramics and stone, has led to the development of some of the most impressive structures in the world.However, despite these achievements, recent events have led to the removal of the Stacbond brand from the market. This is due to the concerns surrounding the safety and fire resistance of some of the company’s products. The Grenfell Tower disaster, which occurred in London in 2017, brought the issue of fire safety for building materials into the spotlight. Subsequent investigations revealed that some of the aluminium composite panels used on the building’s facade did not meet safety regulations. This has led to a review of building safety regulations across the globe, including in the UK, Europe, and Australia.In response to these concerns, the Stacbond Aluminium Composite Panel Company has withdrawn its products from the market, and a review of the company’s manufacturing processes is underway. The company has issued a statement, reassuring customers that it takes the safety and quality of its products seriously and that it is committed to working with regulatory authorities to ensure that its products meet safety standards. It has also promised to continue to invest in the research and development of new, innovative products that meet the changing needs of the industry.Despite the setback, the Stacbond Aluminium Composite Panel Company remains a leading manufacturer of high-quality building materials. The company’s long-standing reputation for excellence, combined with its commitment to safety and innovation, ensures that it remains well-positioned to meet the needs of the market, once regulatory concerns are addressed. The company’s focus on sustainability, as evidenced by its use of recycled materials, also positions it well for the growing demand for sustainable building solutions.In conclusion, aluminium composite panels remain an important part of the construction industry, and the Stacbond Aluminium Composite Panel Company has played a major role in their development. However, the concerns surrounding fire safety regulations have led to the removal of its products from the market. The company’s commitment to safety and innovation, as well as its strong reputation for excellence, ensures that its prospects remain bright as it works to address these concerns and re-enter the market.

Benefits and Applications of Aluminum Honeycomb Sheet for Various Industries

Aluminum Honeycomb Sheet Revolutionizes Construction Industry[City, Date] - In a groundbreaking move, [Company Name], a leading manufacturer of high-quality construction materials, has introduced its latest innovation - the Aluminum Honeycomb Sheet. This product is set to revolutionize the construction industry by offering unparalleled strength, durability, and versatility.[Company Name], renowned for its commitment to excellence and pioneering technologies, has once again pushed the boundaries of construction materials with the introduction of the Aluminum Honeycomb Sheet. This sheet, constructed with a unique honeycomb core sandwiched between two aluminum alloy panels, presents an array of benefits that are poised to reshape the industry.The Aluminum Honeycomb Sheet boasts exceptional strength-to-weight ratio, making it an ideal choice for various construction applications. This innovative design allows for maximum load-bearing capacity without compromising on weight. The lightweight nature of the sheet not only facilitates ease of installation but also significantly reduces transportation costs and equipment requirements.Furthermore, the inherent durability of the Aluminum Honeycomb Sheet ensures long-term performance, even in demanding conditions. Its unique composition enables it to withstand extreme temperatures, corrosion, impact, and structural fatigue, rendering it an ideal choice for both indoor and outdoor applications. This resilience translates into reduced maintenance costs and increased lifespan, providing long-term advantages for contractors and end-users alike.The versatility of the Aluminum Honeycomb Sheet is another unparalleled advantage offered by [Company Name]. With its customizable design and availability in various sizes, thicknesses, and surface finishes, customers can tailor the sheet to suit their specific construction requirements. Whether utilized in interior walls, external cladding, partitions, ceilings, or furniture, the Aluminum Honeycomb Sheet seamlessly integrates into various architectural designs, adding a touch of modernity and sophistication to any construction project.Importantly, [Company Name] places immense emphasis on sustainable practices and environmental responsibility. The Aluminum Honeycomb Sheet aligns perfectly with these principles. Composed of recyclable materials, this product not only minimizes waste but also contributes to the conservation of natural resources. In an era where sustainable construction solutions are paramount, the Aluminum Honeycomb Sheet stands proudly as an environmentally-conscious choice for contractors and developers.Speaking on this revolutionary introduction, [Company Name]'s spokesperson stated, "We are thrilled to unveil our Aluminum Honeycomb Sheet, a game-changer in the construction materials industry. This product showcases our commitment to pushing the boundaries of innovation while keeping sustainable practices at the forefront. We firmly believe that the Aluminum Honeycomb Sheet will redefine construction norms and enable architects, contractors, and developers to explore new possibilities in their projects."Market experts are already lauding the Aluminum Honeycomb Sheet as an industry-disruptive product, foreseeing its quick adoption across a wide range of construction applications. With its exceptional strength, durability, and customizable design, this sheet has the potential to replace traditional construction materials in many areas, heralding a new era of advanced construction techniques.In conclusion, [Company Name] has once again demonstrated its commitment to excellence and pioneering technologies with the introduction of the Aluminum Honeycomb Sheet. This innovative product offers exceptional strength, durability, and versatility, revolutionizing the construction industry. With its unique design, customizable options, and sustainable properties, the Aluminum Honeycomb Sheet is poised to redefine construction norms and set new benchmarks for the industry.

Discover the Versatility and Durability of ACP Panels

Innovative and Eco-Friendly ACP Panels to Revolutionize Building Materials As the global building sector continues to grow, there is an increasing need for eco-friendly building materials that provide a balance between aesthetics, functionality, and durability. Amidst the industry-wide search to find such products, ACP panels have become a popular choice among developers. And, among the many options available, the Mapl ACP panel is gaining traction, thanks to its innovative features that set it apart from other alternatives.Mapl ACP panels are essentially a composite material that combines two aluminum sheets with a thermoplastic core. The result is an incredibly strong and lightweight product, making it ideal for large-scale commercial constructions. However, one of the most notable aspects of these panels is their eco-friendliness. Unlike other traditional building materials like brick, stone, and cement, Mapl ACP panels are highly sustainable and energy-efficient.The company's focus on quality is evident in the manufacturing process. The Mapl ACP panels go through extensive testing to ensure they meet the highest international standards, such as the ASTM, EN, and AAMA. It is why their panels have an excellent fire-resistance rating, making them suitable for high-risk areas. Mapl ACP panels are also resistant to weathering and corrosion, and they can withstand extreme temperatures.Moreover, the company has incorporated innovative features into their panels to enhance their aesthetic appeal. For instance, the Mapl ACP panel comes in a wide range of colors, allowing developers to choose a design that matches the project's style and theme. The panels can also be customized to include various finishes like brushed aluminum, metallic, and glossy.Mapl ACP panels are also easy to install. They come in a standard size, and installation involves basic techniques, making them a cost-effective solution for building projects. Moreover, the panels are highly versatile and can be used in various applications, including cladding, roofing, interior designs, and signage.Apart from these apparent benefits, using Mapl ACP panels also has positive environmental implications. As a sustainable and energy-efficient building material, it helps reduce the environmental footprint of buildings. It also safeguards the typical air quality of the area, especially in urban centers where pollution levels are high.In conclusion, ACP panels are undoubtedly an excellent alternative to traditional building materials, and Mapl ACP panels stand out as a leading brand in this category. Their innovative features, eco-friendliness, and high-quality standards make them an attractive choice, worth considering for all kinds of building projects. With the world becoming increasingly aware of the need to be environmentally conscious, these panels present a solution that is both practical and sustainable.Mapl ACP panels are the way of the future and a positive step towards a greener and more sustainable planet. This eco-friendly alternative to traditional building materials provides developers with an opportunity to construct beautiful and resilient buildings that minimize their environmental impact. As the world progresses towards a sustainable future, it is imperative that more and more developers adopt green building techniques and choose sustainable materials like Mapl ACP panels.

Latest Updates on Aluminum Composite Panel Prices in the Market

Aluminum Composite Panel Price May Increase Due to Rising DemandAluminum composite panels have become increasingly popular in the construction industry in recent years, due to their lightweight, durability, and aesthetic appeal. These panels are widely used in both residential and commercial buildings for their ability to offer a sleek and modern finish, while also providing insulation and weather resistance.However, recent market trends suggest that the price of aluminum composite panels may see an increase in the near future. This is primarily due to the rising demand for these panels in the construction industry, as well as the impact of raw material prices and trade tariffs on the manufacturing processes.{} is one of the leading manufacturers of aluminum composite panels in the industry. The company specializes in producing high-quality panels that are used in a wide range of applications, including exterior cladding, interior decoration, signage, and advertising.With a strong focus on innovation and quality, {} has established a reputation for delivering premium products that meet the needs of architects, builders, and designers. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that their panels meet industry standards and regulations.In recent months, {} has observed a significant increase in the demand for their aluminum composite panels. This surge in demand can be attributed to the growing construction activities across various sectors, including residential, commercial, and industrial projects. As developers and builders seek to incorporate modern and sustainable building materials, the use of aluminum composite panels has become increasingly prevalent.However, the surge in demand has also highlighted the challenges faced by the industry, particularly in relation to the price of raw materials. The cost of aluminum, which is a key component in the production of composite panels, has been on the rise due to various economic and geopolitical factors. This has placed pressure on manufacturers like {}, leading to potential price adjustments to account for the higher production costs.Additionally, trade tariffs and import/export regulations have also had an impact on the pricing of aluminum composite panels. The global trade landscape has become more complex in recent years, with ongoing trade disputes and negotiations affecting the cost of raw materials and finished products. As a result, manufacturers may need to reassess their pricing strategies to remain competitive in the market.Despite these challenges, {} remains committed to providing customers with high-quality aluminum composite panels. The company's focus on sustainable manufacturing practices and efficient production processes has allowed them to navigate the market dynamics effectively. By staying abreast of industry trends and adopting innovative solutions, {} aims to continue meeting the needs of their customers while maintaining their reputation as a reliable supplier of aluminum composite panels.In conclusion, the demand for aluminum composite panels is expected to rise in the coming years, driven by the growth in construction activities and the increasing focus on sustainable building materials. However, manufacturers like {} may face pricing pressures as a result of the higher costs of raw materials and trade regulations. Nonetheless, the company remains dedicated to delivering top-notch products that meet the evolving needs of the construction industry. As the market dynamics continue to shift, {} is well-positioned to adapt to these changes and continue providing value to their customers.

Top Benefits of Composite Plastic Sheets for Various Applications

[Company Name] Revolutionizes the Composite Plastic Sheet Industry with Pioneering Technology[City, Date] - [Company Name], a leading innovator in the advancements of composite materials, has announced its latest breakthrough in composite plastic sheet technology. This revolutionary product is set to transform various industries with its unparalleled strength, durability, and versatility.Composite plastic sheets have gained significant popularity due to their lightweight yet sturdy nature, making them an ideal choice for a wide range of applications. However, traditional composite materials often fall short in terms of strength and resistance to extreme environmental conditions. With its ground-breaking technology, [Company Name] has overcome these limitations, revolutionizing the industry.One of the key advantages of [Company Name]'s composite plastic sheet is its exceptional strength-to-weight ratio. This means that the material is incredibly light, making it easy to handle and transport, while also providing exceptional strength and durability. As a result, this product is ideal for industries such as aerospace, automotive, construction, and marine, where both weight reduction and high strength are crucial factors.Additionally, the composite plastic sheet offered by [Company Name] exhibits excellent resistance to corrosion and chemicals, making it highly suitable for applications in harsh environments. This durability ensures that the product maintains its integrity even in extreme conditions, prolonging its lifespan and reducing maintenance costs.[Company Name] takes immense pride in its commitment to environmental sustainability. The composite plastic sheet is manufactured using recycled materials, reducing the company's carbon footprint and contributing to a greener future. By utilizing innovative manufacturing processes and sustainable sourcing, [Company Name] sets a new standard for eco-friendly composite materials.Furthermore, [Company Name] places a strong emphasis on research and development to constantly improve and expand its product line. The company's team of highly skilled engineers, scientists, and designers work tirelessly to develop new applications and enhancements for the composite plastic sheet. This dedication to innovation ensures that [Company Name] remains at the forefront of the industry, constantly pushing boundaries and driving change.The potential applications for [Company Name]'s composite plastic sheet are vast. In the aerospace industry, the material's lightweight nature can significantly reduce fuel consumption while maintaining the required structural integrity. Moreover, the automotive industry can benefit from improved fuel efficiency, as well as enhanced safety features thanks to the material's exceptional strength.Another industry that stands to benefit greatly from this innovation is construction. The composite plastic sheet's durability, resistance to harsh weather conditions, and low maintenance requirements make it an attractive choice for a wide range of construction projects. Its versatility allows for various uses, including wall paneling, roofing, and insulation, to name just a few.The marine industry is also set to undergo a transformation with [Company Name]'s composite plastic sheet. Boats and yachts constructed with this innovative material will experience improved fuel efficiency, increased buoyancy, and superior resistance to water and salt-induced corrosion. These properties make it an excellent choice for shipbuilding, ensuring vessels are more durable, efficient, and eco-friendly.In conclusion, [Company Name] has revolutionized the composite plastic sheet industry with its groundbreaking technology. The exceptional strength-to-weight ratio, durability, and resistance to extreme conditions set this product apart from its competitors. By focusing on sustainability and investing in research and development, [Company Name] continues to push the boundaries of composite materials. This innovation is set to have a profound impact across industries, from aerospace and automotive to construction and marine, transforming the way we utilize composite plastic sheets and driving positive change towards a more sustainable future.

Durable Aluminum Exterior Wall Panels: A Practical Solution for Your Building

Aluminum Exterior Wall Panels are rapidly becoming a popular choice for building construction and renovation projects. One company at the forefront of this trend is {Remove brand name}, who have been leading the way in innovative and sustainable building materials. Their Aluminum Exterior Wall Panels are known for their durability, versatility, and aesthetic appeal, making them a top choice for architects and developers alike.With a focus on cutting-edge technology and a commitment to environmentally-friendly practices, {Remove brand name} has established itself as a trusted name in the construction industry. The company's Aluminum Exterior Wall Panels are designed to not only enhance the visual appeal of a building but also provide a high level of protection and insulation. This combination of form and function has made {Remove brand name} a go-to choice for projects ranging from commercial high-rises to residential developments.One of the key advantages of {Remove brand name}'s Aluminum Exterior Wall Panels is their lightweight and easy installation. This makes them an ideal choice for projects where time and labor costs are a concern. Additionally, their panels are designed to withstand the elements, making them a durable and long-lasting option for any building exterior.In keeping with their commitment to sustainability, {Remove brand name} uses high-quality recycled aluminum in the manufacturing of their exterior panels. This not only reduces the environmental impact of their products but also results in a higher level of quality and performance. By incorporating recycled materials into their manufacturing process, {Remove brand name} is able to offer a more sustainable and eco-friendly option for building projects.Beyond their environmental benefits, {Remove brand name}'s Aluminum Exterior Wall Panels are also highly efficient in terms of energy consumption. The panels are designed to provide excellent insulation, reducing the need for excessive heating and cooling within the building. This not only saves on energy costs but also contributes to a more comfortable and sustainable living or working environment.Another key feature of {Remove brand name}'s Aluminum Exterior Wall Panels is their adaptability to various design aesthetics. Whether a project calls for a sleek and modern look or a more traditional and timeless appearance, {Remove brand name} has a range of panel options to suit any architectural style. This versatility has made {Remove brand name} a preferred choice for designers and developers who want to achieve a specific look without compromising on performance.In addition to their high-quality products, {Remove brand name} is also known for their exceptional customer service and support. Their team of experts is available to assist with project planning, material selection, and installation guidance, ensuring that every project is completed to the highest standards.As the demand for sustainable and durable building materials continues to grow, {Remove brand name} is well-positioned to meet the needs of the construction industry. Their Aluminum Exterior Wall Panels offer a winning combination of performance, aesthetics, and environmental responsibility, making them a top choice for projects of all sizes and scopes.With a solid reputation for quality, innovation, and reliability, {Remove brand name} has firmly established themselves as a leader in the construction materials market. Their Aluminum Exterior Wall Panels are just one example of their ongoing commitment to providing superior products that meet the needs of today's builders and architects.In conclusion, {Remove brand name}'s Aluminum Exterior Wall Panels are a smart choice for any building project, offering a range of benefits that set them apart from other options on the market. With a focus on sustainability, efficiency, and versatility, {Remove brand name} continues to be a driving force in the construction industry. Whether it's a new development or a renovation, {Remove brand name} is the go-to source for high-quality exterior panels that deliver on both performance and style.